Quality Control

Quality Policy:

1. First priority on Highest Service or Product.

2. Consistently meet on time delivery and providing competitive price.

3. Continuously improve the effectiveness of Quality Managem ent system

4. Ensure consistent compliance to requirement.

Philosophy:

1. Create A Win-Win approach with customers.

2. Produce Value-added Quality Products Service.

3. Go the extra mile in meeting customer' satisfaction

Quality Control Measures:

- Total Quality management (TQM)

- Gemba Zanka

- Continuous Improvement Program

- Employee Training Programs

- Vertical Integration of Processes

- Investment in the Latest Quality Control Equipment

- Quality Incentive Programs

- Organizational Commitment to Quality

From Raw Material incoming to products shipment, we manage every step of the manufacturing process to insure products are made to the clients specifications, All products have to go through 4 checks in the whole process:

Raw material inspection

In processing inspection

Final inspection

Outgoing inspection

Typical Problems with die casting includes:

(1) Air holes, voids, shrinkage

(2) Surface Finish issues, Deburing issues, Powder Coating

(3) Dimensional issues with machining. Thread Tap go/ no-go gauge is often required.

Key points to prevent quality issues in die casting:

(1) Clear communication upfront

(2) Carefully analyze design to anticipate probelms before investing in making die casting molds.

(3) Thorough testing of first article from die casting.

(4) SPC control and mold maintenance in following up production.

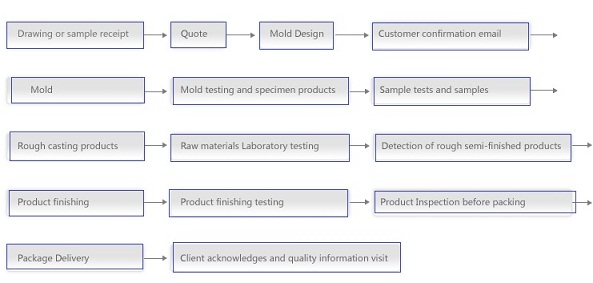

Process Flow:

Testing Equipments:

EMAIL US

EMAIL US SKYPE

SKYPE