- Mold&Tooling making

- Aluminum die casting

- Zinc alloy die casting

- CNC precision machining

- Die cast heat sinks

- Custom Fabrication

- Magnesium die casting

- Metal stamping

- Extrusion

- Silicon products

- Plastic injection molding

- Lighting fixtures die casting

- Communication die casting

- Automotive parts die casting

- Kitchenwares die casting

- Security products die casting

- Motor parts die casting

- Die casting for more industries

Tel: +86-755-28688356

E-mail: info@ljcnc-casting.com

![]()

![]()

![]()

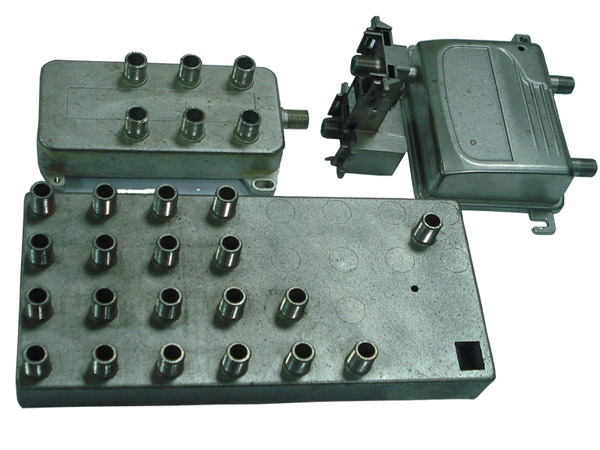

OEM zinc die cast

OEM zinc die cast parts are manufactured for different industries: automotive, lighting, communication, medical, electronic, appliance, OA and computer systems, etc. Our zinc die casting equipments from 80Ton to 280Ton can produce zinc die cast products depending on your specific needs. Our design process assures parts meet exacting specifications and our streamlined manufacturing systems allow us to offer aggressive casting delivery times. Professional one stop services are provided include engineering, designing, prototyping, tooling, and mass production. Besides high quality die casting, we offer secondary services include CNC/CAD-CAM machining, annealing, tumble deburring, cryogenic deburring, vibratory finishing, coatings, painting & electrical plating, assembling.

Details:

OEM zinc die cast parts are manufactured for different industries: automotive, lighting, communication, medical, electronic, appliance, OA and computer systems, etc. Our zinc die casting equipments from 80Ton to 280Ton can produce from 1g to 5kg products depending on your specific needs.

Zinc Alloy Characteristics:

- High strength and hardness

- Excellent electrical conductivity

- High thermal conductivity

- Low cost raw material

- High dimensional accuracy and stability

- Excellent thin wall capability

- Ability to cold form, which eases joining

- High quality finishing characteristics

- Outstanding corrosion resistance

- Full recyclability

Our design process assures parts meet exacting specifications and our streamlined manufacturing systems allow us to offer aggressive casting delivery times. Professional one stop services are provided include engineering, designing, prototyping, tooling, and mass production. Besides high quality die casting, we offer secondary services include CNC/CAD-CAM machining, annealing, tumble deburring, cryogenic deburring, vibratory finishing, coatings, painting & electrical plating, assembling.

Related Products

EMAIL US

EMAIL US SKYPE

SKYPE