- Mold&Tooling making

- Aluminum die casting

- Zinc alloy die casting

- CNC precision machining

- Die cast heat sinks

- Custom Fabrication

- Magnesium die casting

- Metal stamping

- Extrusion

- Silicon products

- Plastic injection molding

- Lighting fixtures die casting

- Communication die casting

- Automotive parts die casting

- Kitchenwares die casting

- Security products die casting

- Motor parts die casting

- Die casting for more industries

Tel: +86-755-28688356

E-mail: info@ljcnc-casting.com

![]()

![]()

![]()

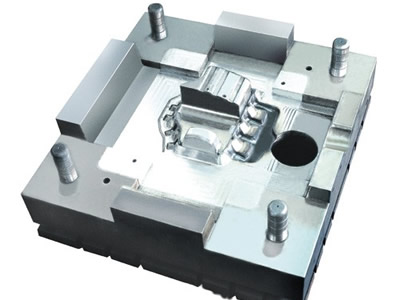

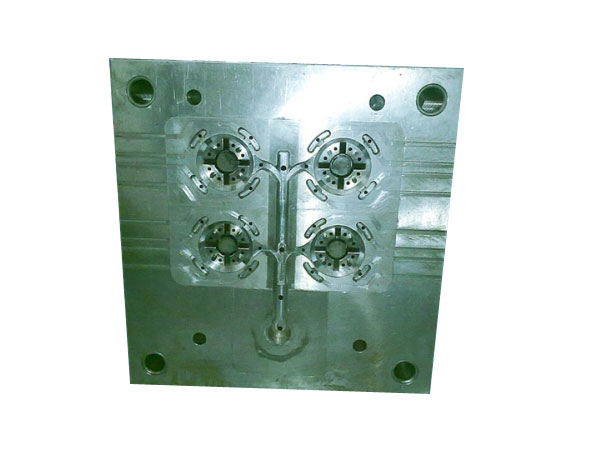

Die casting mould

With rich experience in Aluminium alloy, Zinc and Magnesium alloy die casting mould making and parts die casting, before the die casting mould design, we would provide you with our detailed die casting mold flow simulation report for your approval. After received your final part 3d data, we would provide you with our 3d mould design within 3-5 days. All mould cavity and core steel certified with formal certification, we will use SKD61, 8407 steels etc... for mould cavity and core making. Weekly mould making process report will be sent you with detailed mould cavity pictures.

Details:

With rich experience in Aluminium alloy, Zinc and Magnesium alloy die casting mould making and parts die casting, before the die casting mould design, we would provide you with our detailed die casting mold flow simulation report for your approval. After received your final part 3d data, we would provide you with our 3d mould design within 3-5 days. All mould cavity and core steel certified with formal certification, we will use SKD61, 8407 steels etc... for mould cavity and core making. Weekly mould making process report will be sent you with detailed mould cavity pictures.

Related Products

EMAIL US

EMAIL US SKYPE

SKYPE